Product Name:Laminate flooring production line, laminate flooring machine,

laminate flooring, PVC flooring production line, Parquet floor production line,

Composite cork floor production line, Solid wood floor production line,

Cutting machine, Fibre cement board production line,

Multi rip saw machine

Raw material: MDF board

General process: Hot lamination-rip saw cutting-double end tenoner-paraffining process

- packing line - warehouse storing and ready for shipment.

|

Plane Laminate flooring board production line machines list as below:

| No. |

Machine name |

Machine pic |

| 1 |

2800-3200T short cycle melamine lamination hot press machine

Function: this machine will do the lamination melamine paper, balance paper, Wear-resistant paper and mdf board together, then get the final laminated flooring board.

Remark:

The pressure will be finalized by your mdf baord size, u mdf board size will decide the size of hot platen.

2800T-3200T is for 4x8ft raw material mdf board. |

|

| 2 |

Laminated board cooling line

Function: this cooling line used to do the edge trimming work, laminated mdf board cooling work, then the cooled board will be stacked very well in the ground roller or the board lifter machine.

Remark:

we will manufacturing this cooling line according to u raw material mdf board size. |

.jpg) |

| 3 |

3PCS RIP SAW MACHINE

Function: this machine will do the cutting work on the laminated board, from one big board into 2-3pcs small board.

Remark:

this machine working width and working thickness range can be designed newly, also our quotation will based your required size. |

|

| 4 |

MULTI RIP SAW MACHINE

Function: this machine will be used to do the multi rip sawing work on the board we get from 3PCS RIP SAW MACHINE, the finished board width will be your required width, such as 180mm, 200mm, 400mm...etc. and our sawing machine will be adjustable, u can adjust the cutting width according to u requirements. |

|

| 5 |

Double end tenoner machine

Function: this line including several parts, including the board pusher, conveyor, long side milling machine, middle conveyor, short side milling machine, overturing machine, stacker machine. this machine will be used to do the flooring board locking process on the flooring board.

|

|

| 6 |

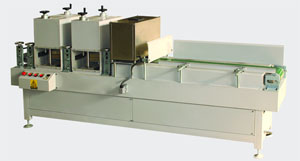

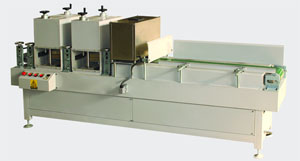

Full automatic flooring board packing line

Function: this machine will be used to do the packing work on the packed flooring board, also including several parts in this line, including the inlet conveyor, bagging machine, hot shrinking machine, cooling section, outlet conveyor and table. |

|

| 7 |

Paraffin spreading machine

Function: this machine including two parts, one paraffin machine will be for long edge of flooring board, another paraffin machine will be for short edge of flooring machine, the work this machine did is spreading the paraffin on the lock processing area, then flooring board will have the result of WATER-PROOF. |

|

| 8 |

Electrostatic dust collector machine

Function: electrostatic dust collector is mainly used in decorative plates, electronics, medical and other industries; low pressure water mist by nanoparticles fretting can solve dust on surface of products completely. low voltage input can reduce energy consumtion and make it much safer while working.

> Removing dust on surface of decorative plates completely

> Low voltage input, the power is only 0.018kw

> Transparent organic glass designing

> Watching intuitively. |

|

| 9 |

Chamfer Painting Machine

This product includes long side painting device, short side painting device, and drying line. Its function is to paint on the chamfer of laminate flooring as well as some other furniture board. the whole machine is controlled by PLC, which can distinguish feeding material automatically. This machine can save 70% of area and 40% of power compared with traditional equipment. the sprayer is adjusted by lead screw to increase precision and enhance stability.

> Automatically feeding-out, saving powers, labors as well as places.

> Precision screw adjust input and output.

> PLC control, with advanced sensor

> Double frequency conversion motor driving, delivering smoothly.

>Short side motor connects directly, decreasing smoothly.

> Working width of drying line can be adjusted freely.

|

|

U profiles Laminate flooring board production line machines list as below:

| No. |

Machine name |

Machine pic |

| 1 |

2800-3200T short cycle melamine lamination hot press machine

Function: this machine will do the lamination melamine paper, balance paper, Wear-resistant paper and mdf board together, then get the final laminated flooring board.

Remark:

The pressure will be finalized by your mdf baord size, u mdf board size will decide the size of hot platen.

2800T-3200T is for 4x8ft raw material mdf board. |

|

| 2 |

Laminated board cooling line

Function: this cooling line used to do the edge trimming work, laminated mdf board cooling work, then the cooled board will be stacked very well in the ground roller or the board lifter machine.

Remark:

we will manufacturing this cooling line according to u raw material mdf board size. |

.jpg) |

| 3 |

3PCS RIP SAW MACHINE

Function: this machine will do the cutting work on the laminated board, from one big board into 2-3pcs small board. and this machine can stack the board cutted very well. the conveying system is via Vaccum loading and unloading.

Remark:

this machine working width and working thickness range can be designed newly, also our quotation will based your required size. |

|

| 4 |

MULTI RIP SAW MACHINE

Function: this machine will be used to do the multi rip sawing work on the board we get from 3PCS RIP SAW MACHINE, the finished board width will be your required width, such as 180mm, 200mm, 400mm...etc. and our sawing machine will be adjustable, u can adjust the cutting width according to u requirements. |

|

| 5 |

Double end tenoner machine

Function: this line including several parts, including the board pusher, conveyor, long side milling machine, middle conveyor, short side milling machine, overturing machine, stacker machine. this machine will be used to do the flooring board locking process on the flooring board.

|

|

| 6 |

Full automatic flooring board packing line

Function: this machine will be used to do the packing work on the packed flooring board, also including several parts in this line, including the inlet conveyor, bagging machine, hot shrinking machine, cooling section, outlet conveyor and table. |

|

| 7 |

Paraffin spreading machine

Function: this machine including two parts, one paraffin machine will be for long edge of flooring board, another paraffin machine will be for short edge of flooring machine, the work this machine did is spreading the paraffin on the lock processing area, then flooring board will have the result of WATER-PROOF. |

|

| 8 |

Electrostatic dust collector machine

Function: electrostatic dust collector is mainly used in decorative plates, electronics, medical and other industries; low pressure water mist by nanoparticles fretting can solve dust on surface of products completely. low voltage input can reduce energy consumtion and make it much safer while working.

> Removing dust on surface of decorative plates completely

> Low voltage input, the power is only 0.018kw

> Transparent organic glass designing

> Watching intuitively. |

|

| 9 |

Chamfer Painting Machine

This product includes long side painting device, short side painting device, and drying line. Its function is to paint on the chamfer of laminate flooring as well as some other furniture board. the whole machine is controlled by PLC, which can distinguish feeding material automatically. This machine can save 70% of area and 40% of power compared with traditional equipment. the sprayer is adjusted by lead screw to increase precision and enhance stability.

> Automatically feeding-out, saving powers, labors as well as places.

> Precision screw adjust input and output.

> PLC control, with advanced sensor

> Double frequency conversion motor driving, delivering smoothly.

>Short side motor connects directly, decreasing smoothly.

> Working width of drying line can be adjusted freely. |

|

Working video of Laminate flooring board line:

(Any inquriy directly to jack.lee@floormachinery.com)

|